Maso Automotives / Infrastructure

Infrastructure

Raw Material Cutting

CNC Circular Saw – fully automatic bar cutting machines with auto trim piece segregation system and fully programmable.

Dies & Tool Manufacturing

Complete tool room set up for manufacturing of Dies & tooling for all varieties of components like Yokes, flanges, Gears, Shafts, Bevel Gears and Near net shape gears like Spurs & Hypoid, etc.

Design Department

Design & Development is done with the latest software - Delcam & ProE whereas, Forge 2009 from Transvalor is used as Simulation Software.

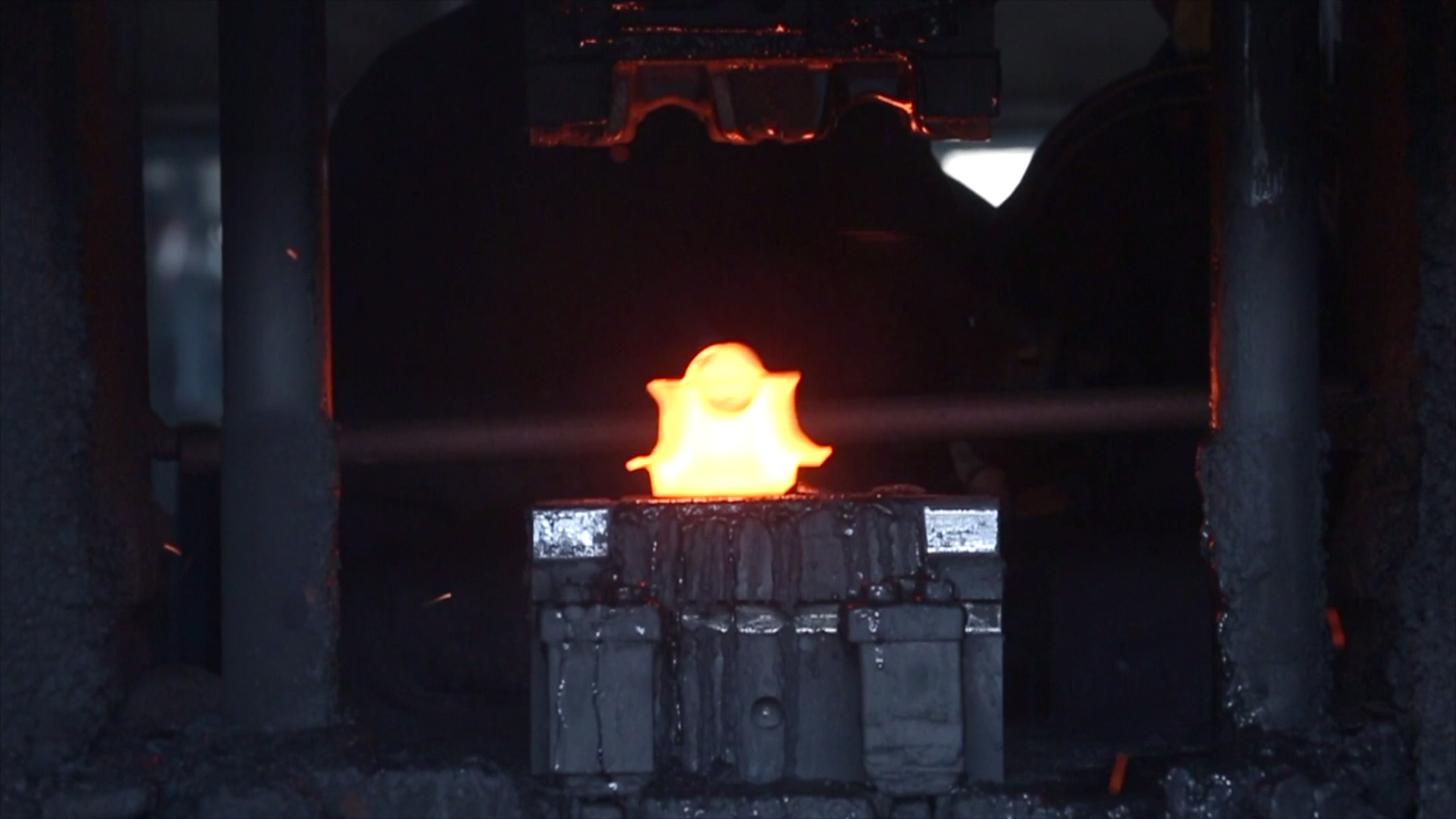

Metal Forming Division

MASO has a Metal Forming Division having state of art forging facility:

- Presses 1300 Ton /1600 Ton/ 2500 Ton (2 No’s) capacity

- Up setters with the range 1 ½”, 3”, 4”

- All of the above with induction heaters, optical pyrometers and accept/reject system.

- Ring Rolling Facility for manufacturing Ring Gears

Heat Treatment

- Heat treatment back up of 1600 Kg per hour for all kinds of processes like Normalizing, Iso Annealing, Hardening & Tempering Process.

- We have existing 2 PLC-based Gas Fired HT plants as of now reducing pollution and increasing efficiency of a furnace by 25% - 40%.

- Multiple Shot blasting facilities are also available.